Developed to increase the automotive test capability of an Ascott cyclic chamber, this new accessory adds 6 very important test standards to their capabilities; ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Scania STD4319.

Developed to increase the automotive test capability of an Ascott cyclic chamber, this new accessory adds 6 very important test standards to their capabilities; ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Scania STD4319.New Products

CR1 Test Panels for ASTM B117 now available – In Stock

SHOP HERE NOW: ASTM B117 Test Panels

Why ASTM B117 Test Panels Are Essential

The ASTM B117 salt spray test is one of the most widely used corrosion testing standards. To achieve repeatable and reproducible results, it is vital to check the corrosivity of the chamber using ASTM B117 test panels. During continuous operation, apparatus verification should be carried out every 3 months.

Benefits of the Test Panels

-

- Manufactured and tested to ISO 3574

-

- Supplied with a Certificate of Conformance and a UKAS Test Certificate

-

- Packaged in VCI corrosion-inhibiting paper and vacuum-sealed aluminium wrapping

-

- Fully compliant for use in ASTM B117 test procedures

Technical Specifications

-

- Material: Cold Rolled Steel CR1

-

- Size: 76mm x 127mm (±0.2mm)

-

- Thickness: 0.8mm (±0.2mm)

-

- Pack Size: 20 panels

-

- Product Code: ACC144

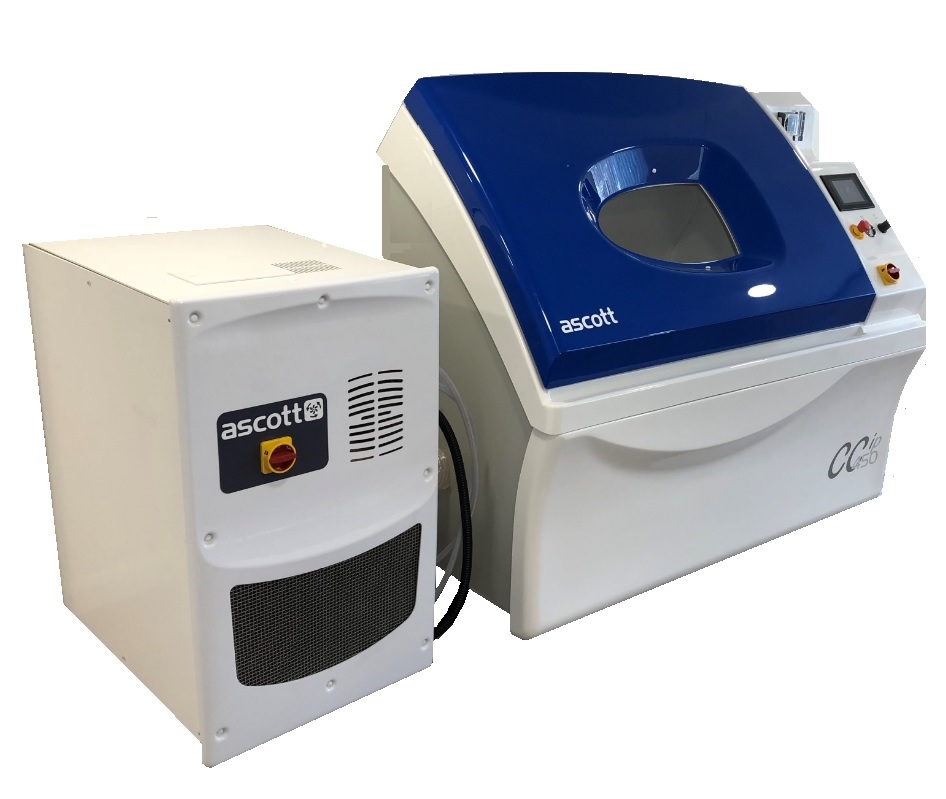

New Accessory: EcoCool Temperature & Humidity Control Unit ACC125/1

The ACC125 Eco Cool is a free-standing, air-circulating chiller and dehumidifier that uses a secondary cooling medium instead of traditional refrigerants. This design removes the need to comply with complex F-Gas regulations. The unit draws air from the main chamber, chills and dehumidifies it, then returns it via insulated inlet piping. This process reduces minimum achievable operating temperature and humidity, delivering superior environmental control at lower running costs. As the system removes heat from the chamber, it releases it into the surrounding room. Maintain room conditions between 18 °C and 23 °C, with a maximum relative humidity of 85%, to ensure optimal performance. Key features:

- Secondary cooling technology – no F-Gas compliance required

- Improved temperature and humidity stability

- Lower operating costs compared to traditional systems

Compatible with corrosion test standards including:

- FORD CETP00.00-L-467

- GMW14872

VW PV1210

VW PV1210- IEC 60068-2-52

- ISO 11997-1

- ISO 16701

The ACC125 Eco Cool is fully compliant with major global corrosion testing standards, making it an ideal upgrade for precision environmental testing.

CO2 Corrosion chamber Options

There is a new EU Regulation 2024/573, in force from 01.01.2025 which details requirements for new equipment in the category of “self-contained refrigeration systems”, where the refrigerant contained must have a GWP (Global Warming Potential) limit of >150.

Ascott are extremely proud to be the first Corrosion chamber manufacturer, to come to market with CO2 cooling technology inside our refrigeration units.

The CO2 cooling technology that we use has a GWP of 1, which is a huge reduction in GWP to the gas used previously- R449A (GWP1397) which was contained within the units.

The new innovative technology is immediately available for all cooling units from Ascott:

· ACC112 with ambient control

· ACC29 sub-zero deep freezing to -20°C

· ACC29 sub-zero deep freezing to -40°C

· All Ascott Atmosfar chambers

The new Ascott cooling units not only meet the requirements of F-Gas regulation refrigeration, but also offer improved performance and efficiency. The energy consumption is heavily reduced, and this also results in quieter operation of the units

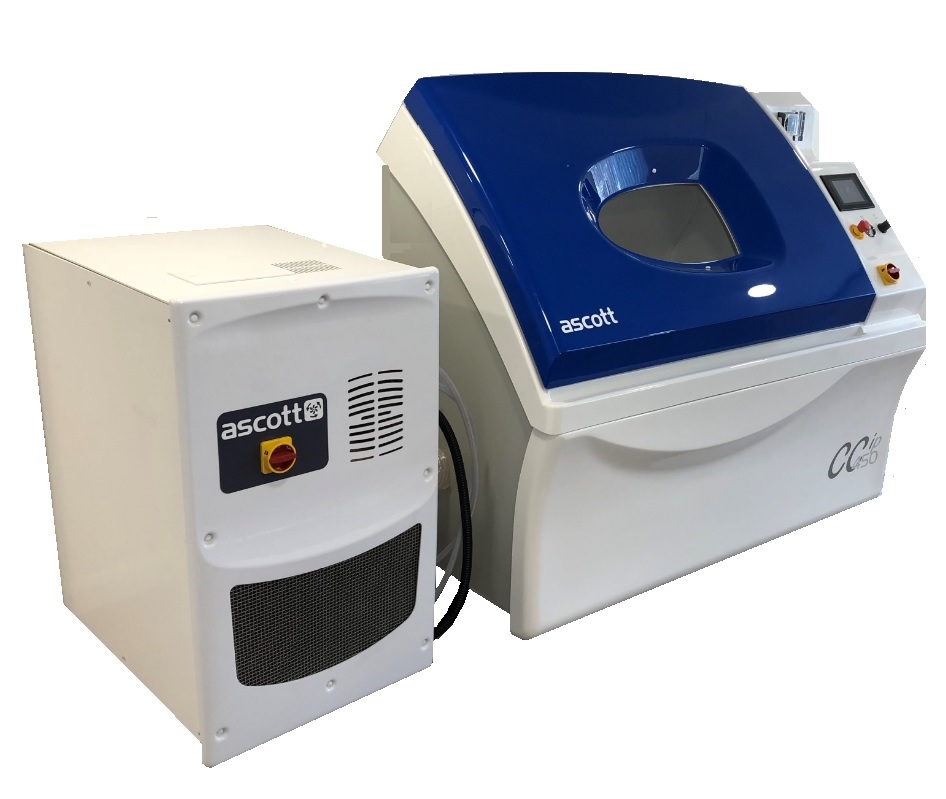

Front Loading 300L Chambers

Maximum Performance, Minimal Footprint!

Designed for small samples/low volumes, or where floorspace is at a premium, our new 300L chambers deliver Ascott innovation in a compact footprint. These innovative front loading chambers have an angled interior roof to prevent condensation droplets falling onto samples, giving reliable, reproducible results in testing and also offer optional cooling to -20°C/ -4°F (with refrigeration unit contained within footprint) Our new compact chamber is small in size but big on features, with a range of additional accessories available to suit your application. Available to order now in the following models: S300iS/ S300iP/ CC300iP For more information, or to request a quote, please contact us Download the Ascott Compact 300L Chamber Brochure here

Designed for small samples/low volumes, or where floorspace is at a premium, our new 300L chambers deliver Ascott innovation in a compact footprint. These innovative front loading chambers have an angled interior roof to prevent condensation droplets falling onto samples, giving reliable, reproducible results in testing and also offer optional cooling to -20°C/ -4°F (with refrigeration unit contained within footprint) Our new compact chamber is small in size but big on features, with a range of additional accessories available to suit your application. Available to order now in the following models: S300iS/ S300iP/ CC300iP For more information, or to request a quote, please contact us Download the Ascott Compact 300L Chamber Brochure here

Kesternich SO2 Humidity Chambers

Ascotts latest product is the Kesternich SO2 Humidity chamber, with fully automatic SO2 Dosing function, available in floor standing or table top 300L Capacity. The KH300 simulates acid rain in a controlled temperature environment to evaluate the relative corrosion resistance of the coating or substrate. The test method is defined by various common standards,ISO 6988, DIN 50 018, ASTM G87, ISO 3231, ISO 22479 are the most popular. The parts to be tested are exposed to warm, moist air in combination with a certain amount of sulphur dioxide. The Ascott Kesternich chamber utilises our latest innovative control system to inject SO2 into the chamber in quantities of 0.2L, 1L or 2L in accordance with the relative standard.

Ascott Kesternich SO2 Chamber 2021

Ascott Kesternich SO2 Chamber 2021

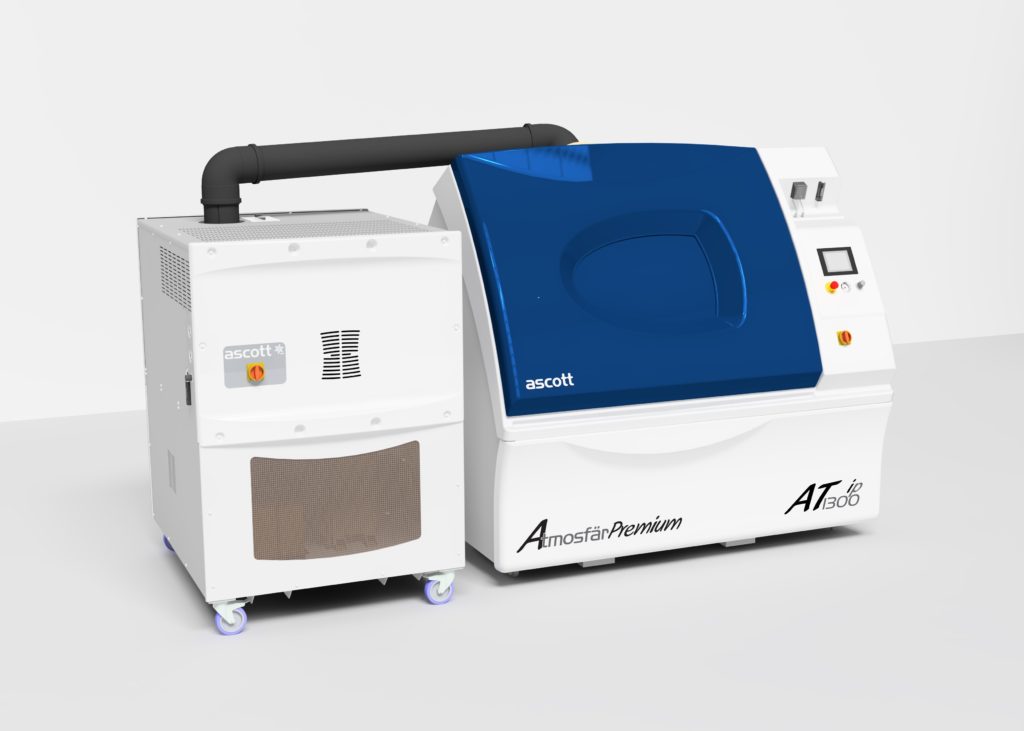

AtmosfärPremium Chambers

The latest generation of Atmosfär chamber, which we call the AtmosfärPremium model range, includes the most comprehensive specification, multiple test standard compliance, accuracy and repeatability of test results. Specifically designed to run the widest range of automotive corrosion test standards, including VW PV1209, VW PV1200, Hyundai CCT-A, Hyundai CCT-B and many more, with a maximum test temperature range of -40C to +80C , combined with salt spray, air drying, wetting, controlled humidity and ambient drying, the AtmosfärPremium is truly without equal in the world of corrosion testing.  Ascott AtmosfarPremium Brochure 2021

Ascott AtmosfarPremium Brochure 2021

ISO 9227 / VDA 233-102 Test Panels

Ascott can now offer CR4 test panels in accordance with the specification in ISO 9227 and VDA 233-102. The panels are supplied as standard with a Certificate of Conformance and UKAS approved test certificate in accordance with ISO 3654. For further information or to buy online, click here  ACC131 – ISO 9227 Test Panels

ACC131 – ISO 9227 Test Panels

CorroFlex Corrosion Chambers

Developed as a flexible capacity range of corrosion chambers, the new CorroFlex range is available in salt spray and cyclic corrosion derivatives, in a wide variety of dimensions. Specifically developed to allow the testing of large, heavy and difficult to handle test specimens.  Ascott CorroFlex Brochure 2021

Ascott CorroFlex Brochure 2021

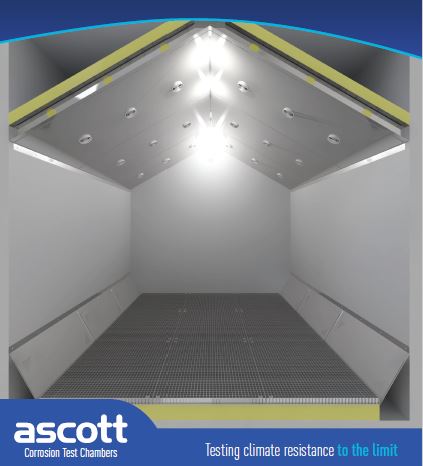

Walk-in/Drive-in Corrosion Test Rooms

Developed to accommodate the increasing demand for testing larger and heavier components, Ascott is now able to offer walk in corrosion and climatic rooms. For further details see the News section.

Developed to accommodate the increasing demand for testing larger and heavier components, Ascott is now able to offer walk in corrosion and climatic rooms. For further details see the News section.

Ford / Volvo / Scania Upgrade kit for Cyclic (CC) Chambers

Developed to increase the automotive test capability of an Ascott cyclic chamber, this new accessory adds 6 very important test standards to their capabilities; ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Scania STD4319.

Developed to increase the automotive test capability of an Ascott cyclic chamber, this new accessory adds 6 very important test standards to their capabilities; ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Scania STD4319.AtmosfärLite

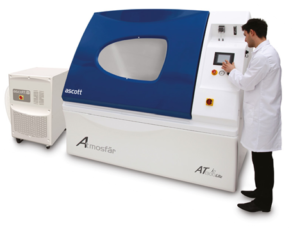

The Atmosfär family of test chambers was developed to meet the most demanding automotive corrosion test standards that require tight control of temperature down to -40°C, with controlled humidity and precision pluviometry. However … many popular automotive test standards do not require such extreme temperatures. The NEW AtmosfärLite is for advanced automotive test standards with temperatures >20°C, including:

- ISO 16701, Ford CETP 00.00-L-467, Volvo VCS 1027,149 (ACT-1), Volvo VCS 1027,1449 (ACT-2), Volvo STD 423-0014, Volvo STD 1027,1375, GMW14872, CCT1 & CCT2, VDA621-415, Scania STD4319