Cyclic Specifications

Cyclic Corrosion Equipment Specifications for Ascotts range of Equipment.

| Wetting mode | Temperature range | Adjustable from ambient to +70°C/+158°F |

| Humidity range | Fixed at 95% – 100% RH | |

| Salt spray mode | Temperature range | Adjustable from ambient to +60°C/+140°F |

| Salt spray fall-out rates | Adjustable from 0.5 to 2 ml per 80 cm² per hour (Option ACC01 increases fallout rate up to 5.5 ml per 80 cm² per hour, Option ACC25 increases fallout rate from 2 – 4 ml per 80 cm² per hour) |

|

| Drying mode | Temperature range | Adjustable from ambient to +70°C/+158°F (Option ACC47/8-13 increases the maximum temperature to 80°C/ 176°F) |

| Humidity range | Uncontrolled | |

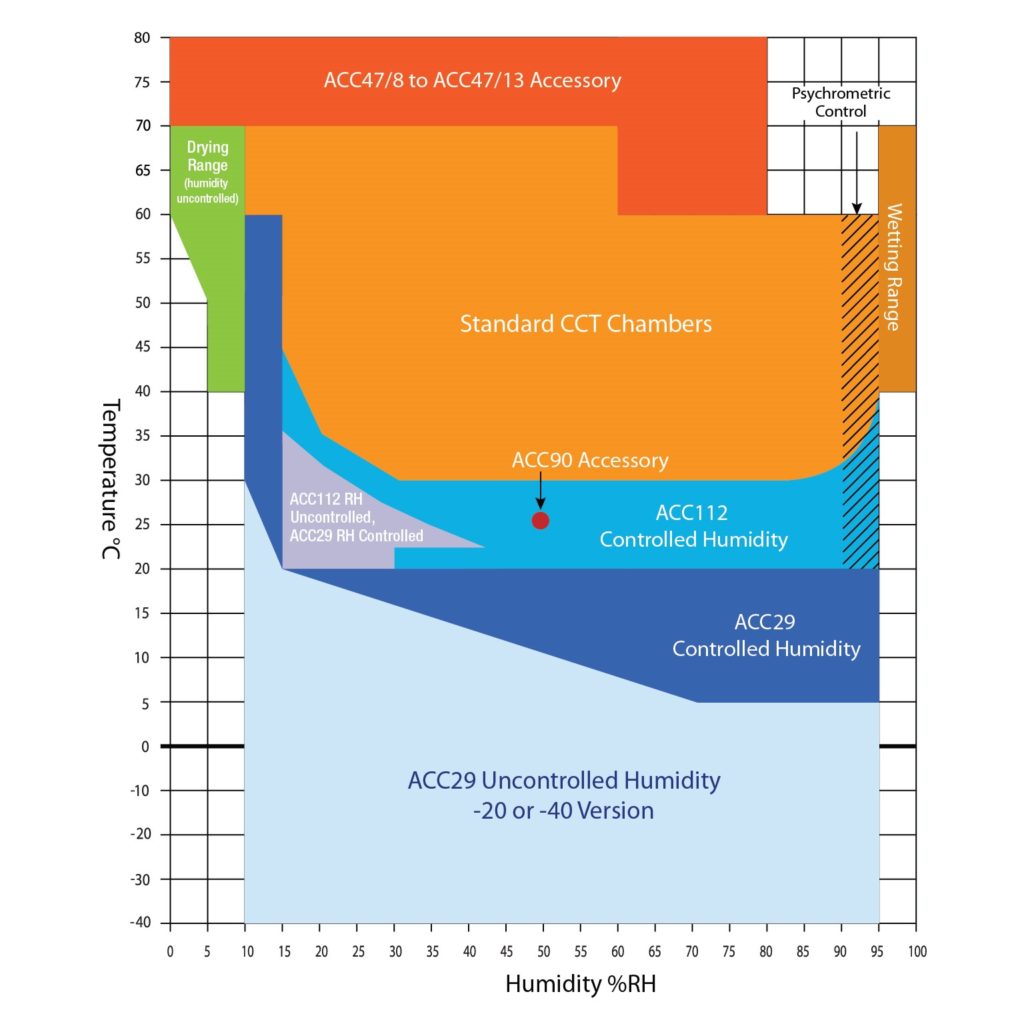

| Controlled humidity mode | Temperature/humidity range | See below graph |

Cyclic Specifications – Performance Graph |

||

|

Adjacent graph showing standard range of temperature/humidity control for an Ascott cyclic corrosion chamber and how this may be extended by the addition of optional accessories.

Contact us for further Information. |

|

|

|

|

|

|

|

||

| Cyclic corrosion test chambers | CC300iP | CC450iP | CC1000iP | CC1300iP | CC2000iP | CC2600iP | |

| Chamber Capacity | 300 Ltrs/ 10.5cu ft |

450 Ltrs/ 15.8cu ft |

1000 Ltrs/ 35.3cu ft |

1300 Ltrs/ 45.9cu ft |

2000 Ltrs/ 70.6cu ft |

2600 Ltrs/ 91.8cu ft |

|

| Mounting Format | Floor standing | Floor standing | Floor standing | Floor standing | Floor standing | Floor standing | |

| Loading threshold | 110mm/43.3″ | 800mm/31.5″ | 800mm/31.5″ | 800mm/31.5″ | 800mm/31.5″ | 800mm/31.5″ | |

| Chamber external dims, max | W | 1450mm/57″ | 1660mm/65.4″ | 2025mm/80.0″ | 2025mm/80.0″ | 2885mm/113.6″ | 2885mm/113.6″ |

| D | 769mm/30″ | 840mm/33.1″ | 1145mm/45.0″ | 1316mm/51.8″ | 1205mm/47.5″ | 1316mm/51.8″ | |

| H | 2010mm/80″ | 1510mm/59.5″ | 1720mm/67.5″ | 1965mm/77.4″ | 1720mm/67.5″ | 1965mm/77.4″ | |

| Chamber internal dims, max | W | 855mm/34″ | 1010mm/39.5″ | 1350mm/51.0″ | 1300mm/51.2″ | 2160mm/85.0″ | 2160mm/85.0″ |

| D | 601mm/24″ | 640mm/25.0″ | 980mm/38.5″ | 980mm/38.5″ | 980mm/38.5″ | 980mm/38.5″ | |

| H | 711mm/27″ reducing to 407mm/16″ | 1140mm/45.0″ | 1320mm/52.0″ | 1500mm/59.0″ | 1320mm/52.0″ | 1500mm/59.0″ | |

| Salt solution reservoir ext. dims. | W | 560mm/22.0″ Dia | 425mm/16.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia |

| D | 620mm/24.0″ Dia | 425mm/16.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia | 540mm/21.0″ Dia | |

| H | 675mm/26.0″ | 630mm/24.0″ | 635mm/25.0″ | 635mm/25.0″ | 635mm/25.0″ | 635mm/25.0″ | |

| Extra Reservoir capacity? –see optional accessories: ACC59 | |||||||

| Sample racks? see optional accessories: ACC16,ACC17,ACC18 | |||||||

| Chamber construction | Glass reinforced plastic, Polypropylene & ABS parts | ||||||

| Color | 9 standard colours to choose from free of charge | ||||||

| Temperature range | Adjustable from -20°C/ -4°F to +70°C/+158°F (Dependant on accessories ordered) | Adjustable from -40°C/ -40°F to +80°C/+176°F (Dependant on accessories ordered) | |||||

| Salt spray fall-out rates | Adjustable from 0.5 to 5.5 ml per 80 cm² per hour (Dependant on accessories ordered) | ||||||

| Electricity supply | 3 phase | 3 phase | 3 phase | 3 phase | 3 phase | 3 phase | |

| Voltage (VAC) and frequency (Hz) dependant on country/region of installation | |||||||

| Water | Deionized/distilled for topping up air saturator and making salt solution. Air saturator requires a continuous water connection 2.5-5.0 bar (36-72 psi). If ACC42 is ordered the continuous water supply must be pressuried 4.0 – 5.0 bar (58-72 psi). If air saturator is topped up manually option ACC66 must be ordered. | ||||||

| Air | Clean dry & oil free, 4.0 to 6.0 bar (58-87psi) with 440 Ltrs (15.5cu.ft) per minute flow | ||||||

| Exhaust | Exhaust – 3m (10ft) exhaust pipe is required which should be terminated outside building (see accessory ACC58) | ||||||

| Drain | 3m (10ft) drain pipe is required which should be terminated into floor level drain (see accessory ACC58) | ||||||

| Operating environment conditions | +18 to +23°C (+64 to 73°F), 85% max RH (non condensing) ambient. | ||||||