Accommodates test panels over a range of thicknesses and at the right angle

Many Ascott customers test for corrosion resistance using test panels (also called coupons) which represent the material and surface coatings, used for the finished product. Not only are these test panels available in a variety of materials and finishes, but they are also available in a wide range of widths and heights, as well as different thicknesses.

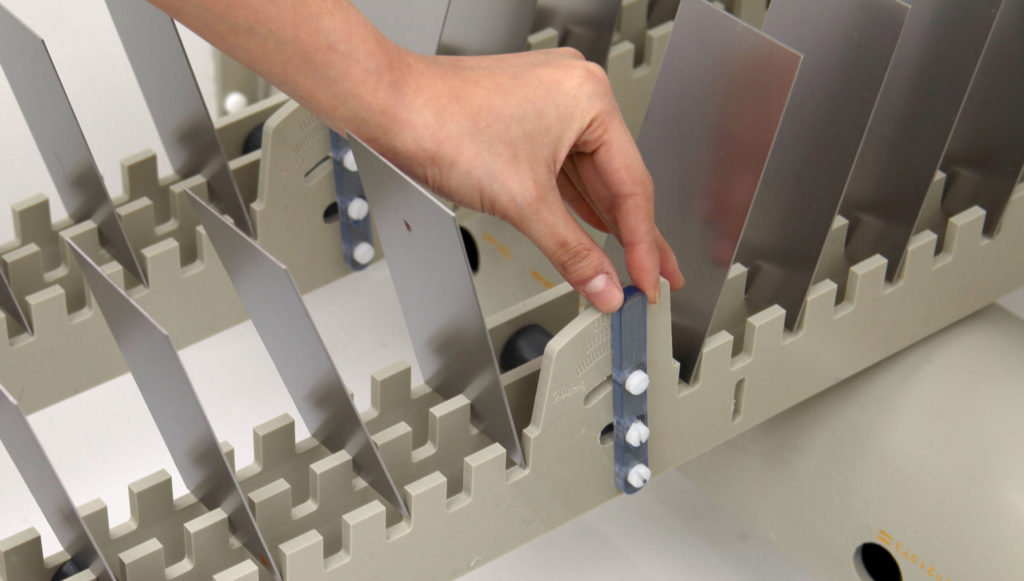

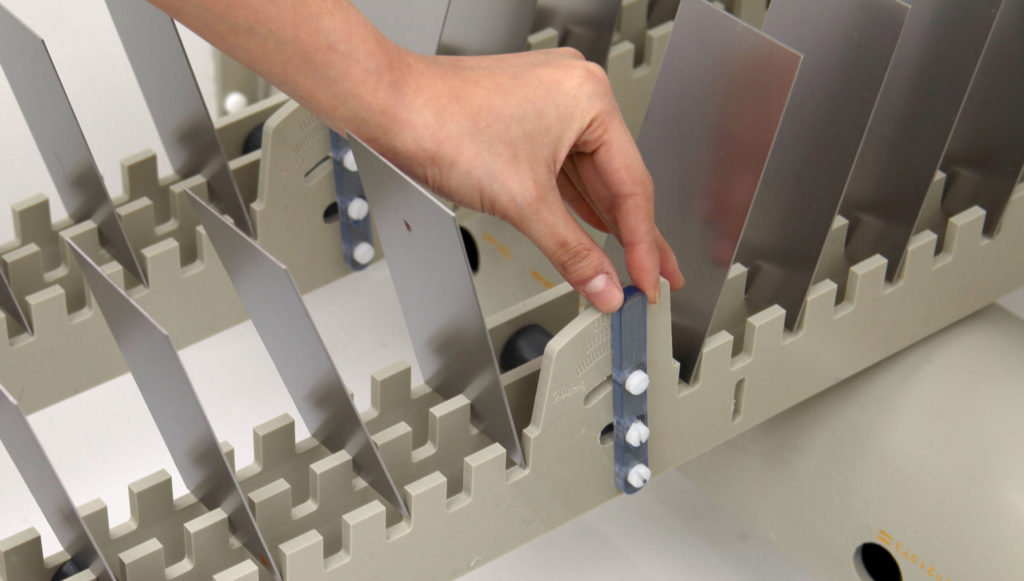

Once a customer has chosen the most suitable test panel for their application, these panels then have to be accommodated within the corrosion test chamber using a slotted sample rack which enables the test panel to incline at the correct angle from vertical, in accordance with the requirements of the test standard they wish to test to.

There are, therefore, many variables to be taken into account when testing panels.

To simplify this, Ascott have recently introduced a new range of sample racks which are available as optional accessories across our chamber product range and which feature an ingenious way of adjusting the slot width (up to 6mm thick) and angle of inclination (0 to 20 degrees from vertical). This is a major advantage over fixed slot width/angle racks because these can not generally accommodate test panels over 3mm thick and below this thickness the panels tend to ‘lean’ at an angle greater than the angle at which the slots have been cut, which may mean them not being tested at the angle required by the test standard.

In addition, the construction of these racks is an open form (top to bottom) to allow the ready passage of air through them. This helps to ensure a uniform distribution of the atmosphere around the samples during testing.

Now available to buy via our online store at www.ascottshop.com

| ACC14/1 |

Slotted Sample Rack – 450L chambers – variable angle – Upper Support Level |

| ACC14/2 |

Slotted Sample Rack – 450L chambers – variable angle – Lower Support Level |

| ACC14/3 |

Slotted Sample Rack – 1000-2600L chambers – variable angle – Upper Support Level |

| ACC14/4 |

Slotted Sample Rack – 1000-2600L chambers – variable angle – Lower Support Level |

| ACC14/5 |

Variable Angle Sample Rack – Atmosfär Chambers with carry handle – Lower Support Level |