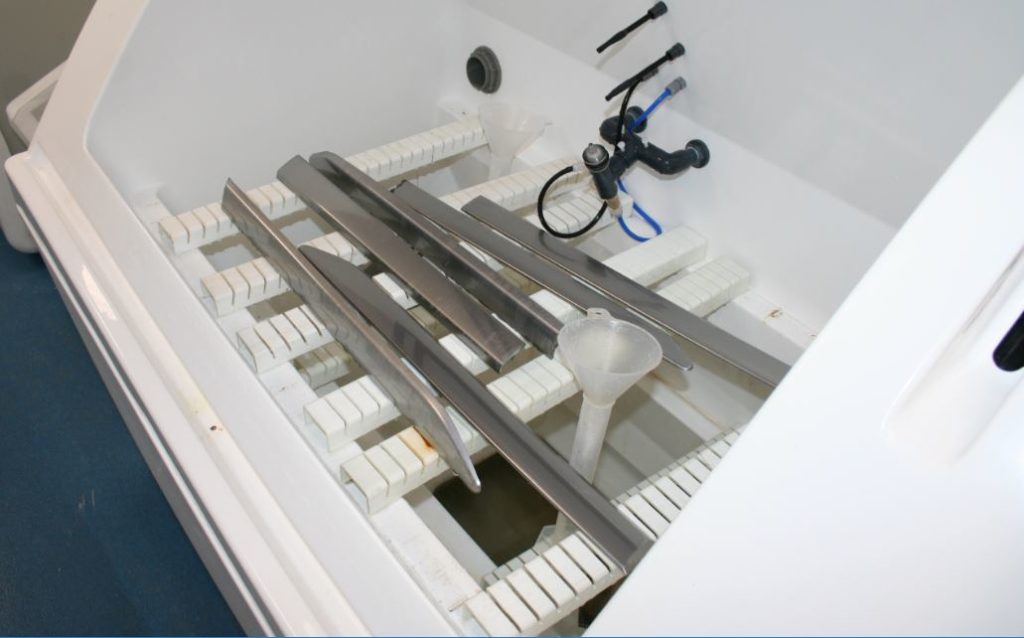

Many Ascott chamber customers regularly (or constantly) undertake tests on very small components, which can be a challenge to contain within the chamber.

Frequently the only way to hold these samples is for the customer to create a holder themselves, or for very small specimens they sometimes have to use string to suspend the samples underneath the standard sample racks.

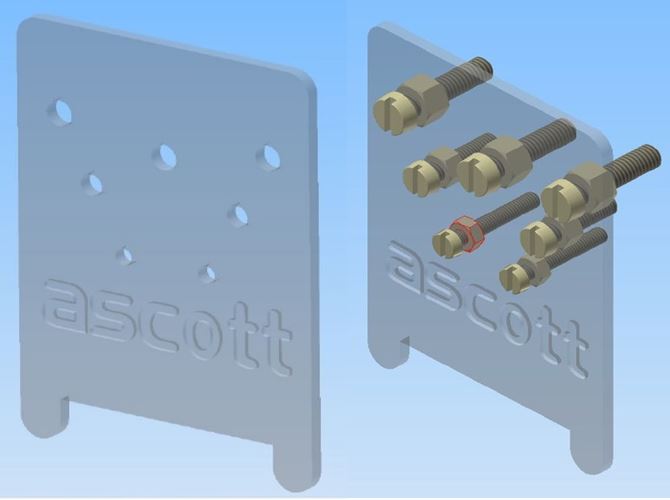

The Ascott development team thought that there must be a better way of holding these small components inside the chamber.

The team found an ideal solution by reengineering the backing plate from the GM test plate kit.

By drilling a series of holes in the backing plate and filling these with a series of nylon nuts and bolts a flexible system for holding small components has been created.

The plate is supplied with 7 drilled and tapped holes (3 x 6mm, 2 x 5mm, 2 x 4mm) which are fitted with the nuts and bolts;

-3 of them with fitted with an M6 x 25 nylon nut and bolt

-2 of them with fitted with an M5 x 20 nylon nut and bolt2 of them with fitted with an M4 x 25 nylon nut and bolt

When loaded with samples the plate slots in to the standard slotted sample racks supplied with each Ascott chamber.

The plate can be used in different ways, if the nuts and bolts are removed the holes can be used to suspend samples directly (as long as the samples do not fall through the hole), or small samples with a through hole (nuts, washers etc.) can be suspended on the bolts.