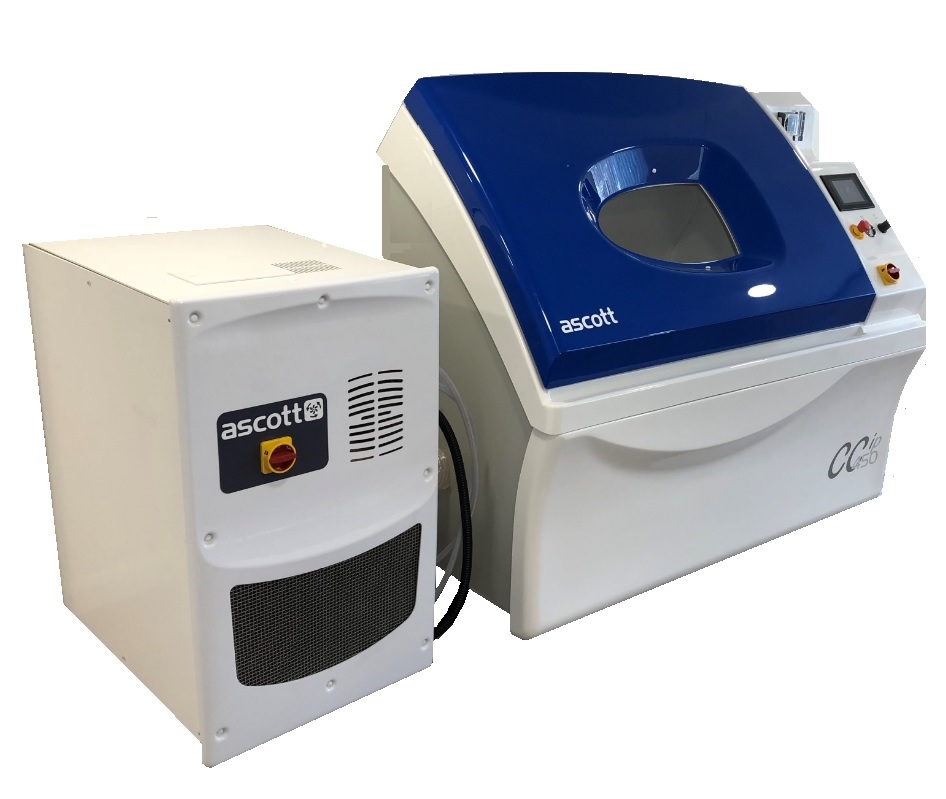

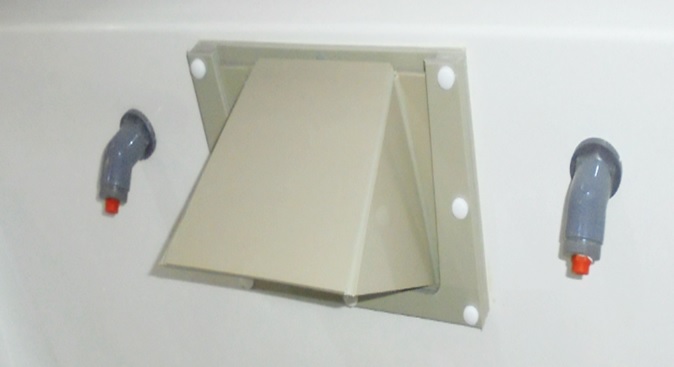

Ascott are adding a new accessory for Alpha + range, an accessory for the H500 condensation cabinet, a ‘Cleveland’ style roof.

This style of cabinet is based on a model originally designed and developed by the Cleveland Society of Paint Technology, this particular design simulates natural dew and rain by condensing moisture directly on to the test panels as opposed to condensate forming on a roof and dripping onto the samples.

With the Cleveland style roof the test panels provide the actual roof of the cabinet, room air on the top side of the panel cools them to a couple of degrees below the vapour temperature, this temperature difference allows the condensate to form directly on the underside of the test panels.

It is only when water condenses that it begins to attack metals and metallic coatings, with the traditional humidity cabinet the samples are inside the cabinet and there is no guaranteed mechanism for cooling the samples enough to generate condensate, with the Cleveland style system the cooling effect of the room air on the back side of the panels ensures there is a continuous supply of freshly condensed water on the test panel.

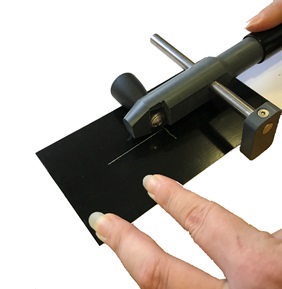

The roof is configured for testing the most popular test panel sizes, 6” x 3” (152mm x 76mm) and 6” x 4”(152mm x 101mm).

The Alpha + ‘Cleveland’ Style condensation cabinet allows testing to the following standards;

DIN50017/ ISO 6270-1/VDA621-421

Volvo STD423-0018,

ASTM D4585

BS3900/ASTMD2247