Cyclic Corrosion Chambers – Key Features

Ascott cyclic corrosion cabinets – one of the world’s most sophisticated and versatile corrosion test systems available, combining salt spray with other environmental conditions such as controlled humidity, drying and wetting.

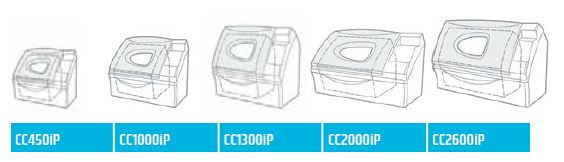

Six model sizes:

-

-

-

- 300 Ltr (10.5 cu ft)

- 450 Ltr (15.8 cu ft)

- 1000 Ltr (35.3 cu ft)

- 1300 Ltr (45.9 cu ft)

- 2000 Ltr (70.6 cu ft)

- 2600 Ltr (91.8 cu ft)

-

-

- As standard they come with the ability to create 6 distinct climates:

• Salt spray

• Condensation humidity (wetting)

• Forced air drying

• Temperature Only

• Ambient drying

• Controlled humidity

These may be programmed to occur in any sequence and be repeated automatically. A wide range of optional accessories enable additional climates to be added to further extend the number of climates and conditions that can be created. -

Extensive optional testing facilities:

Image shows CC300IP Compact front loading chamber Extensive range of optional testing facilities, such as refrigeration and liquid immersion. Click here for the list of optional accessories for custom configuration.

-

All Ascott Cyclic Corrosion Test chambers feature:

-

- Low loading threshold for ergonomic loading and unloading.

- ‘Easy Open’ pneumatically operated canopy, with safety interlock.

- Dry seal gasket to prevent wetting the operator’s clothes.

- Timed canopy lock and automatic purge of the cabinet interior with fresh air after testing and before the chamber is opened.

- Easily accessible salt spray atomizer(s) in transparent hard-wearing acrylic, for ease of maintenance.

- External portable salt solution tank for ease of cleaning. 73L for 450L Chambers and 90L for 1000L Chambers and above.

- Central viewing window for unimpeded visual access to chamber interior and test material.

- Base castors and integrated fork lift truck runners, for ease of transportation.

- Choice of canopy colour.

- Calibration certificate.

- Consumables spares kit.

- Fallout Measuring Kit

- Intuitive 7” full colour touch-screen controller, employing the latest version of our highly intuitive operating software, for ease of programming and use.

- The operating software has a very large capacity memory for 254 multi-step cyclic programmes, 200 sub programmes and 254 single step/single set point programmes can be created and stored in the controller’s system memory, so that the widest possible range of test profiles can be accommodated.

- The icon based control interface offers a variety of languages built-in for ease of understanding and use.

- RJ45 communications port enabling the chamber to be wired or wireless connection to a local area network (LAN) for logging and remote programming via a computer running optional software.

- A real-time, user configurable ‘clock’ to enable different test samples to be batched and have their exposure time monitored separately, with alarms to warn when a pre-set test period has been completed.

-

Click here to watch a video on the overview of our Ascott Cyclic Chambers

For further information contact us on the form below, alternatively, to speak with one of our sales representatives call us on +44 (0) 1827 318040